Chemical Strengthening

Starting in the mid 1960's AGP was one of the first to take chemical strengthening technology out of the laboratory and into commercial markets. This included small appliance glass and components necessary for the production of large scale desalinization membranes. Chemical Strengthening or chemical ion exchange (IOX), is a process that enriches the outer surface of sodium-based glass with larger potassium ions. This technique results in a high surface compression layer on the glass, therefore increasing the nominal impact strength by roughly 3 to 5 times that of ordinary annealed glass. Chemical strengthening is an economical process and is especially well suited for thin glass, curved or shaped glass that cannot be thermally tempered.

- Increased Strength 3 to 5 times.

- Ideal for:

- Thin Glass

- Curved Glass

- Shaped Glass

- No Roller Wave

- No Optical Distortion

- Economical

- Max Glass Size - 96” x 39”

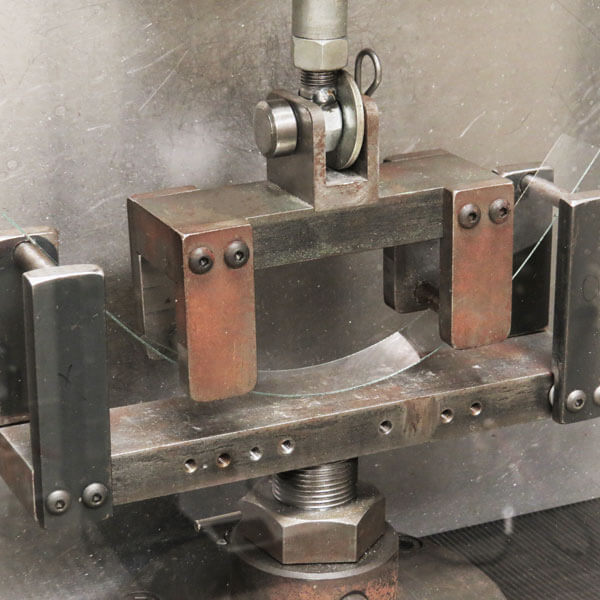

Four Point MOR (Modulus of Rupture) Strength Test for chemically strengthened glass test coupon.

Chemically strengthened ultra-thin glass

Chemically strengthened flow meter tube sight glasses